You may have the most well-built tilt-up, precast, or cast-in-place project, but if the building face has scratches, dents, cracks, or paint delamination, it's your reputation that will need repairs (and maybe the building, too). It is essential to understand why strength, dimensional stability, impact and scratch resistance, and paint adhesion affect the final appearance of the project.

As the industry leader in cosmetic patching, detailing, and smoothing of tilt-up panels, precast, and formed work, Rapid Set® WunderFixx® concrete patching compound has been used on over 30 million square feet of concrete nationwide.

Field and lab test results, with WunderFixx compared to a new material, show WunderFixx maintaining its original, pristine appearance while the other material cracks, crumbles, and shows divots. For this test, the new material will be called Competitor A. Both materials were mixed by hand in the field at the equivalent of 8.0 quarts of water per 50 pounds. The new product was unworkable at this water dosage and the water needed to be increased to 10.4 quarts to achieve a workable consistency.

Strength: Withstands wear and damage from the environment

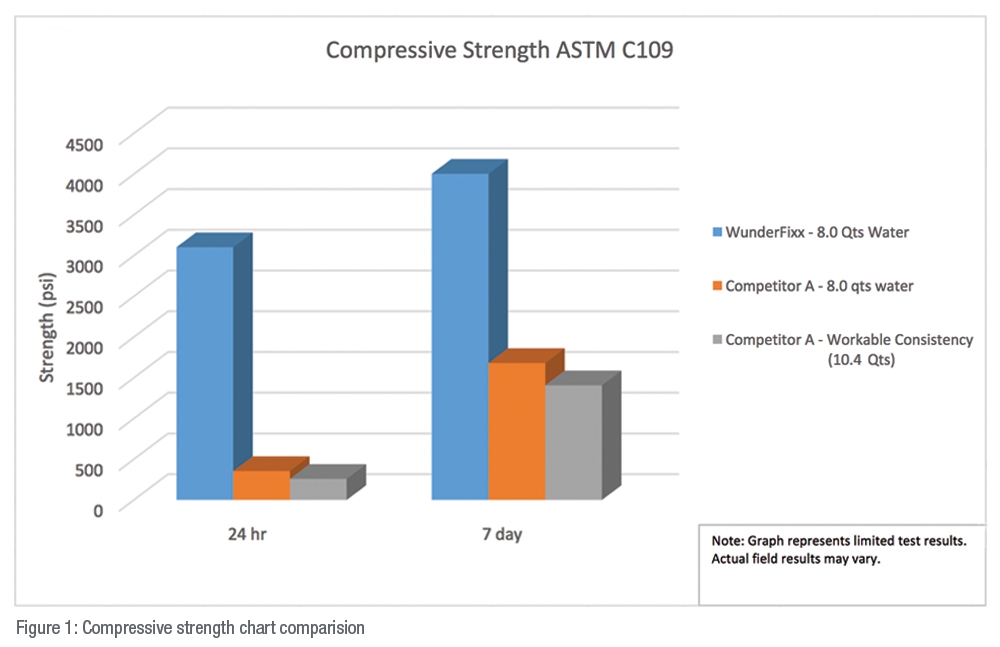

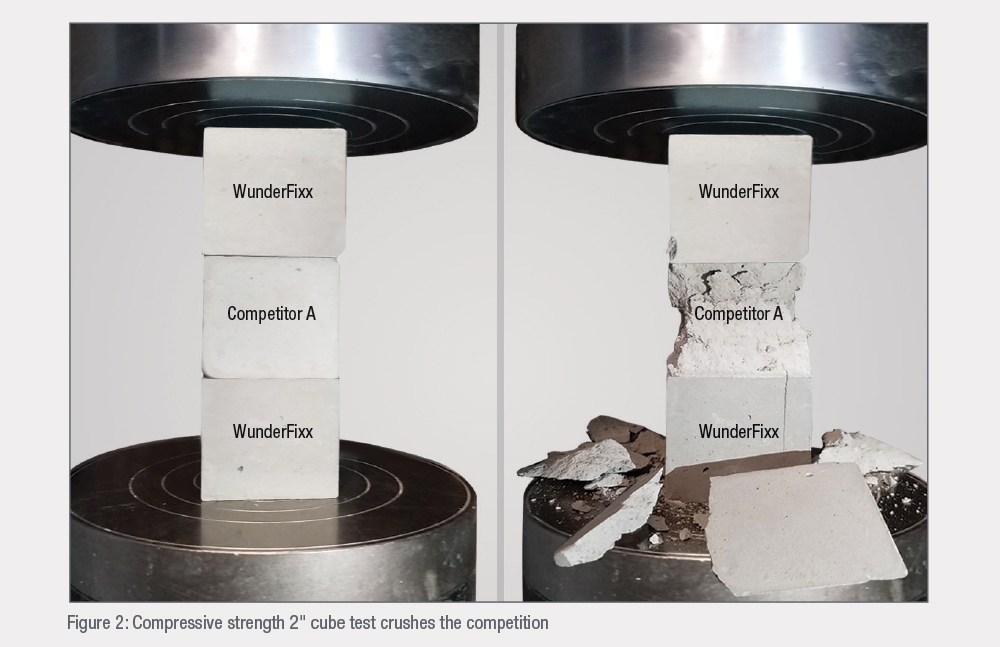

Both materials were tested for compressive strength in 2-inch cubes per ASTM C109. The bar graph results in Figure 1 show the compressive strength average of two cubes at various ages. Increased mix water reduces compressive strength. Rapid Set WunderFixx far exceeds the compressive strength of the competitor regardless of water dosage. Due to this vast difference, a second test was performed to measure strength. In Figure 2, two 2-inch cubes of WunderFixx were placed in the compressive testing apparatus in such a way that they sandwiched a 2-inch cube of Competitor A. When the load was applied, the WunderFixx literally crushed Competitor A, further demonstrating the exceptional compressive strength of WunderFixx.

Dimensional Stability: Less shrinkage means greater durability

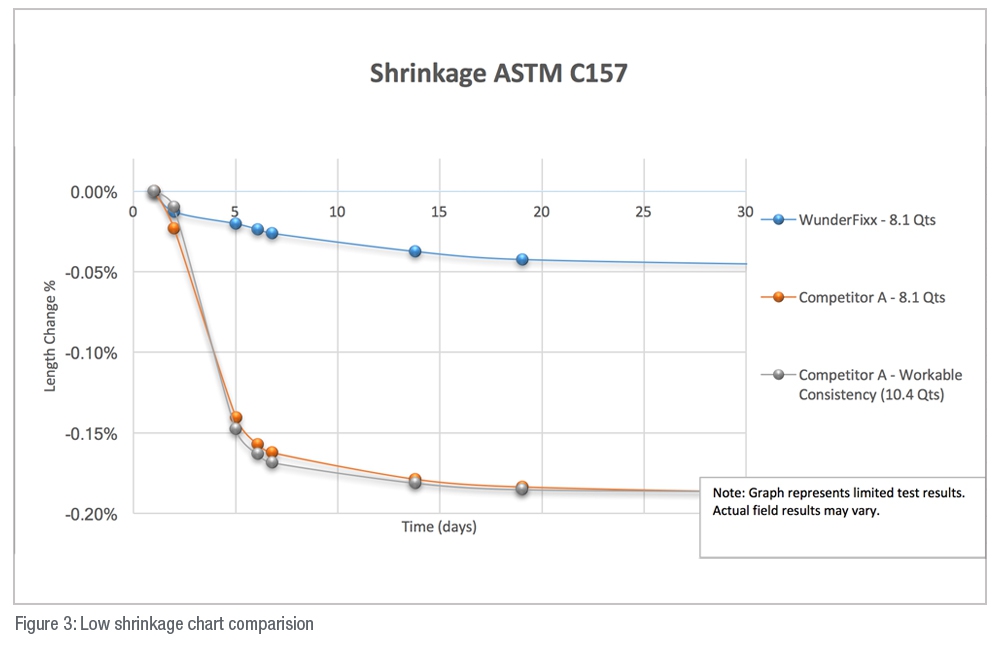

It is common knowledge that excessive shrinkage leads to cracking. WunderFixx was tested by ASTM C157 for length change against Competitor A at the same water dosage and also at a workable consistency. The results in Figure 3 are for the average of two 1"x1"x10" bars. WunderFixx exhibits very low shrinkage, leading to reduced cracking and greater durability.

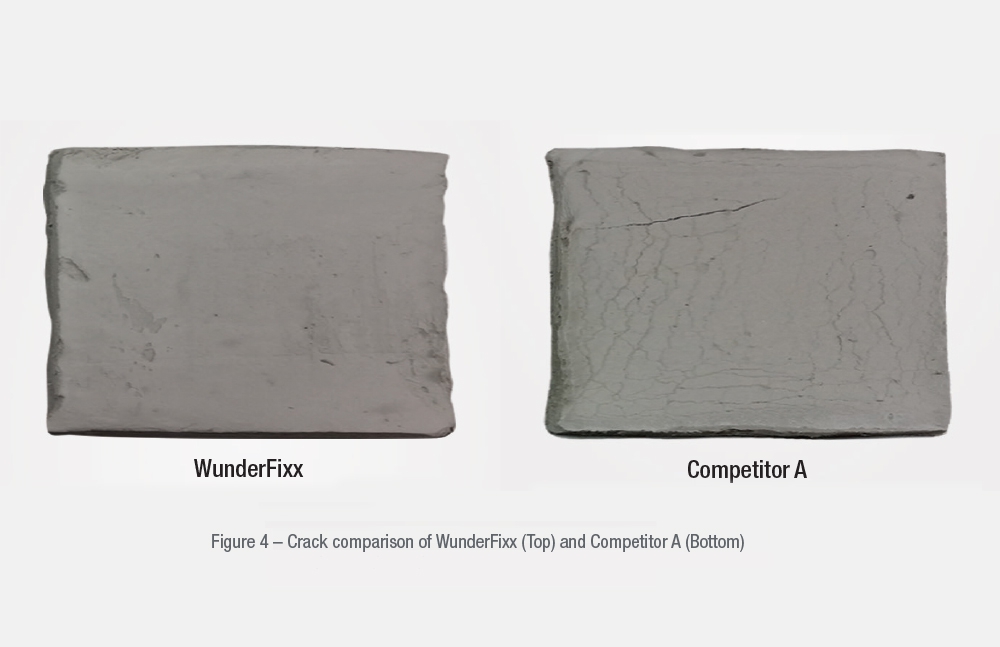

WunderFixx and Competitor A were mixed at a workable consistency and placed on a test panel at the maximum allowable thickness of 1/2-inch. The image in Figure 4 demonstrates that Competitor A has excessive cracking and WunderFixx is crack-free. This proves that high shrinkage can lead to devastating results in the field.

Impact and Scratch Resistance: Achieve a pristine appearance for decades

Long-term durability is critical to the success of a project. The ability to resist impact and scratching is a key component of durability.

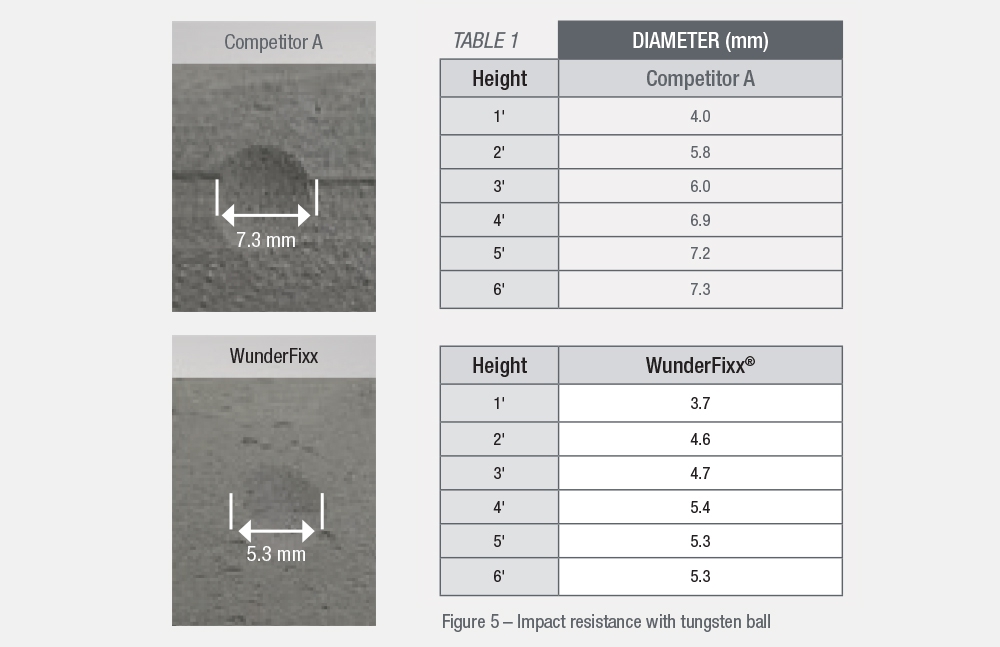

First, the products were tested for impact resistance. A 5/8-inch tungsten ball was dropped on each sample from heights ranging from 1 foot to 6 feet. The diameter of the resulting divot was then measured. Table 1 in Figure 5 summarizes the results. At each height tested, the divot in Rapid Set WunderFixx is smaller. This proves that WunderFixx has better impact resistance than the competition.

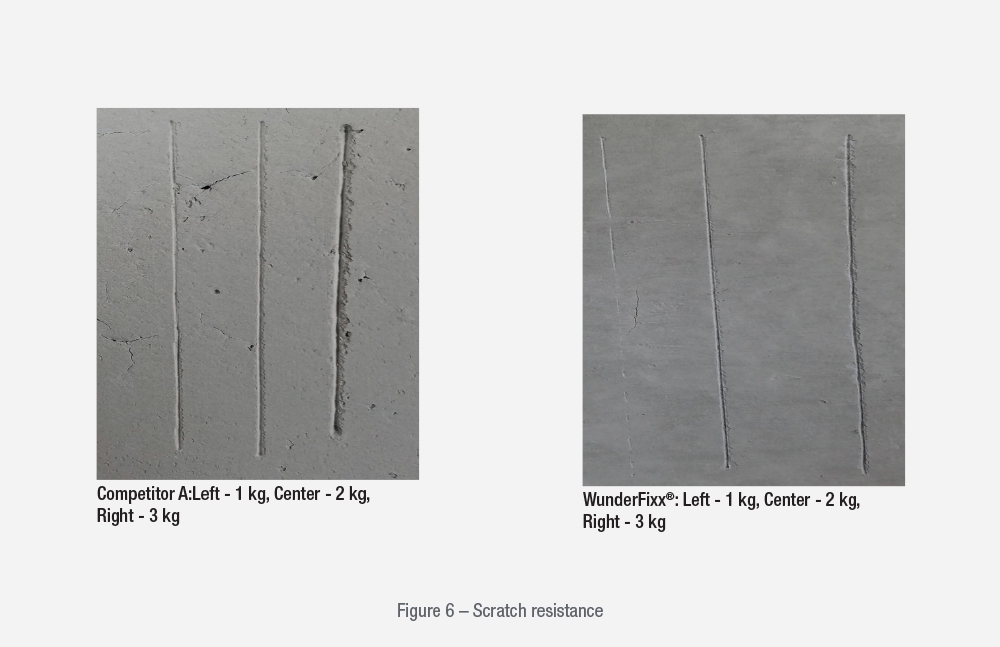

Next, both WunderFixx and Competitor A were tested with a spring-loaded carbide tipped scratch testing apparatus. The tester can provide a load of 1 kg, 2 kg and 3 kg. In Figure 6, the following photos shows the difference between the two materials when scratched with these standard loads. The 1-kg force scratch is on the left, the 2-kg force is in the middle, and the 3-kg force is on the right in each photo. Clearly, the WunderFixx provides better scratch resistance than the competitor.

Paintability and Adhesion: The final touch

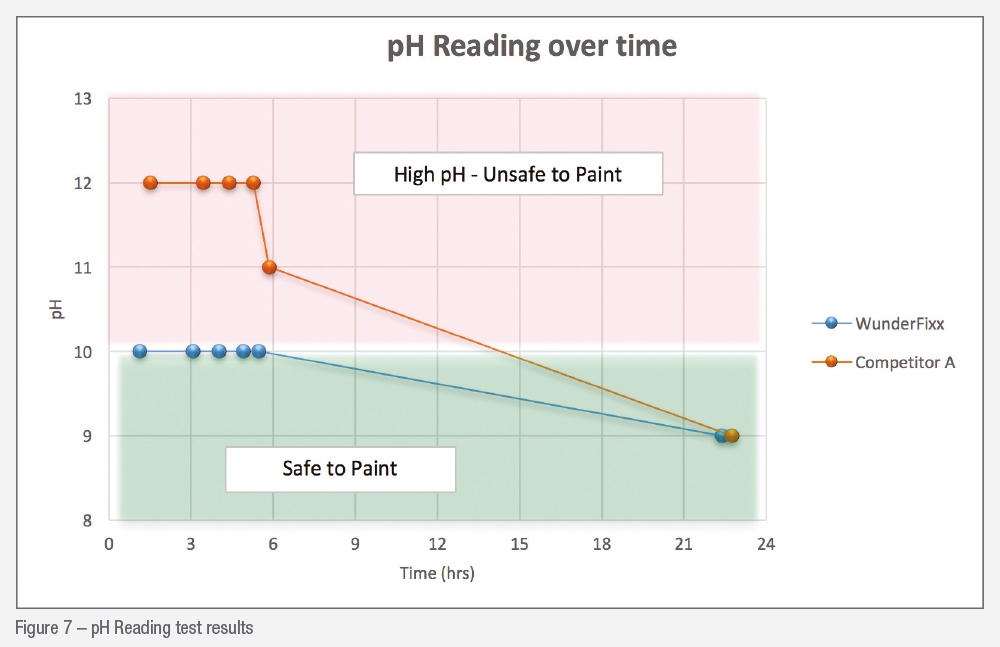

Most tilt-up buildings are painted. Newly placed cement products often have a high alkalinity, or high pH, which can lead to flashing or discoloration of paint. In addition, paint adhesion is of prime importance. The last thing the owner wants to see is paint discoloring or peeling off their new building.

Most exterior coatings, such as paint, require the pH to be around 10 or below to prevent flashing or discoloration. To determine the pH of the materials in this test, a drop of pH-neutral distilled water was placed on the surface and a standard pH strip was pressed onto the droplet. The color was then matched to the guide. This test was repeated hourly up to six hours and then again at 24 hours. The graph, Figure 7, shows that the pH of Rapid Set WunderFixx measured 10 in the very first hour after placement while Competitor A measured 12 up to five hours, reduced to 11 at six hours, and finally dropped below 10 when measured at 24 hours. This test was performed in laboratory conditions; while field conditions may vary, the chemistry of the Rapid Set® Cement used in WunderFixx allows the pH to rapidly drop to levels acceptable for paint. This allows the user to patch, sand, and paint the same day with confidence the paint will not expose the location of the patches.

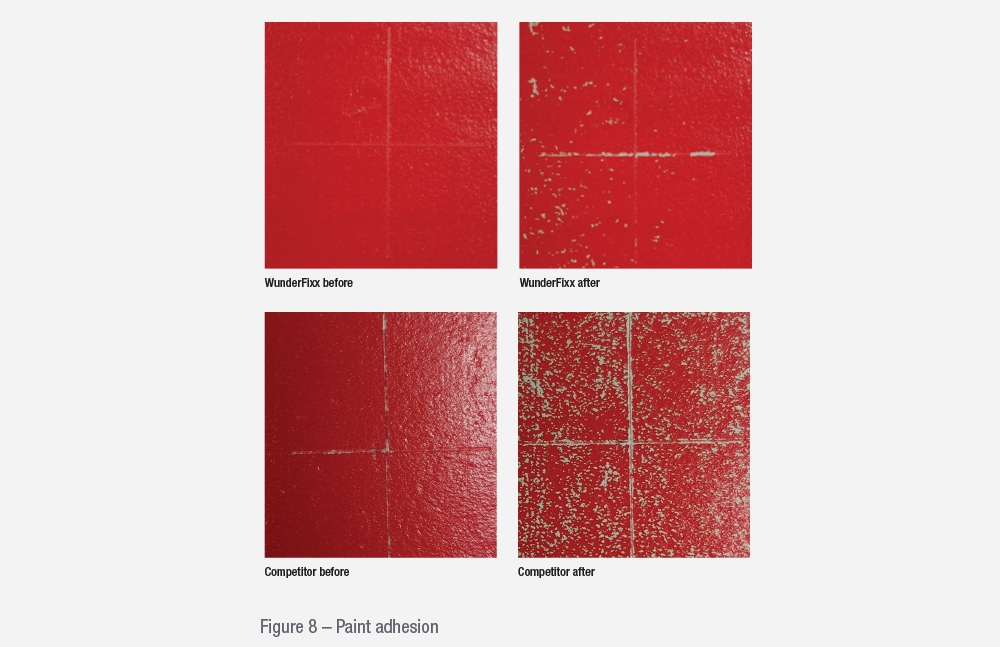

ASTM D3359 was used to measure the adhesion of the paint to WunderFixx and Competitor A. In this test, a painted sample is scored with a razor blade through the paint to the substrate. A piece of pressure-sensitive tape is applied over the scored section and quickly ripped off. The surface of the material is then observed and rated to determine how well the paint adhered to the substrate. Figure 8 show that the paint adheres far better to WunderFixx than to the competitor.

The Bottom Line

The test results indicate that Rapid Set WunderFixx provides better workability at a lower water dosage, has far greater strength, significantly better impact and scratch resistance, can be painted sooner, and allows better paint adhesion. It is therefore easier to use, more resistant to cracking, has greater durability, and is expected to look better longer.

The next time you're choosing your concrete smoothing compound, remember this — strength, dimensional stability, impact resistance, and overall durability positively affect the results and final appearance of your tilt-up jobs.