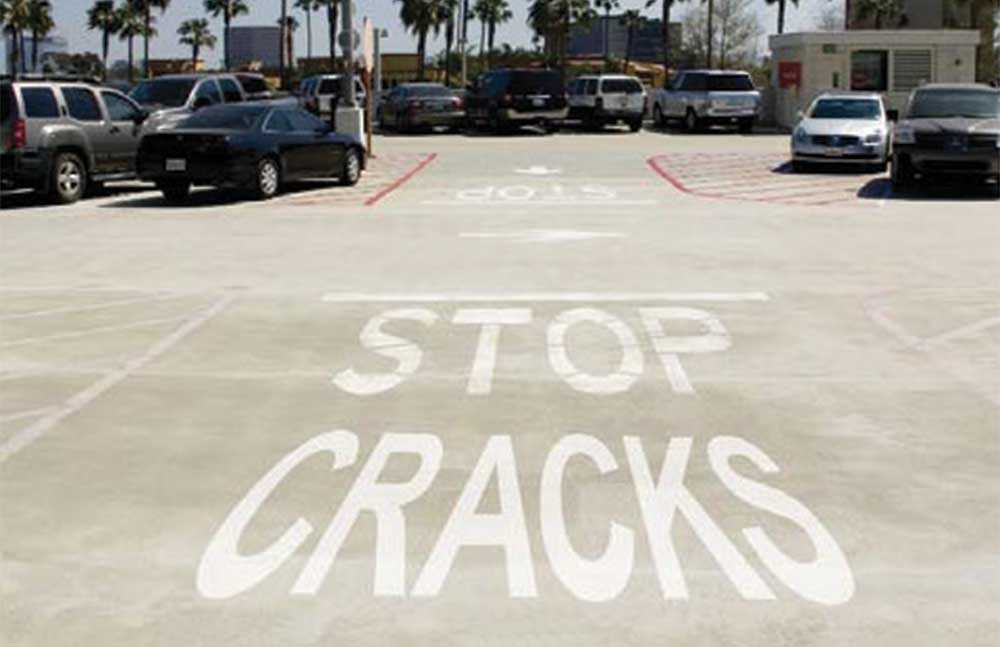

This is the story of a beautiful marriage between two technologies: post-tensioning and shrinkage compensating concrete. The happy couple resides at John Wayne Airport in Santa Ana, CA, on Levels 2 and 3 of parking structures A2 and B2. After nine years of hosting traffic for an airport that serves nearly ten million passengers per year, they still look like they’re on their honeymoon. The concrete decks, each approximately 175 ft wide X 1200 ft long, are in nearly flawless condition. According to airport spokesperson Jenny Wedge, “They have required minimal to no maintenance.”

The story of the successful match on Levels 2 and 3 is actually built, both literally and figuratively, on a failure on Level 1. The matchmaker who arranged the happy union is an engineer with a theory that links one of the most humble, common aspects of concrete (drying-shrinkage cracking) to one of the mightiest forces on the planet – the earthquake.

HOW THE TWO TECHNOLOGIES MET

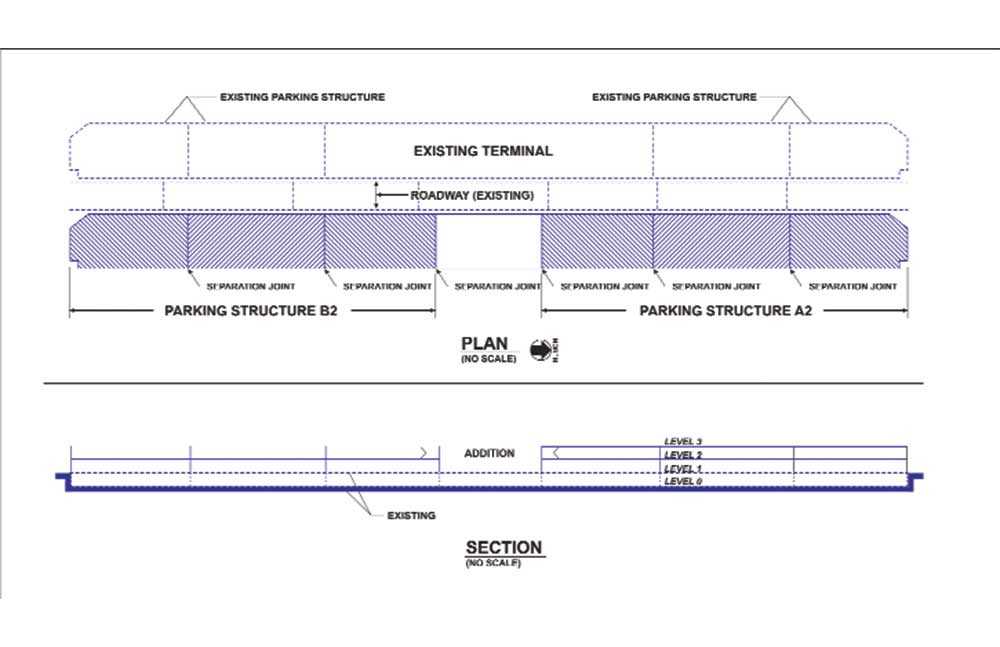

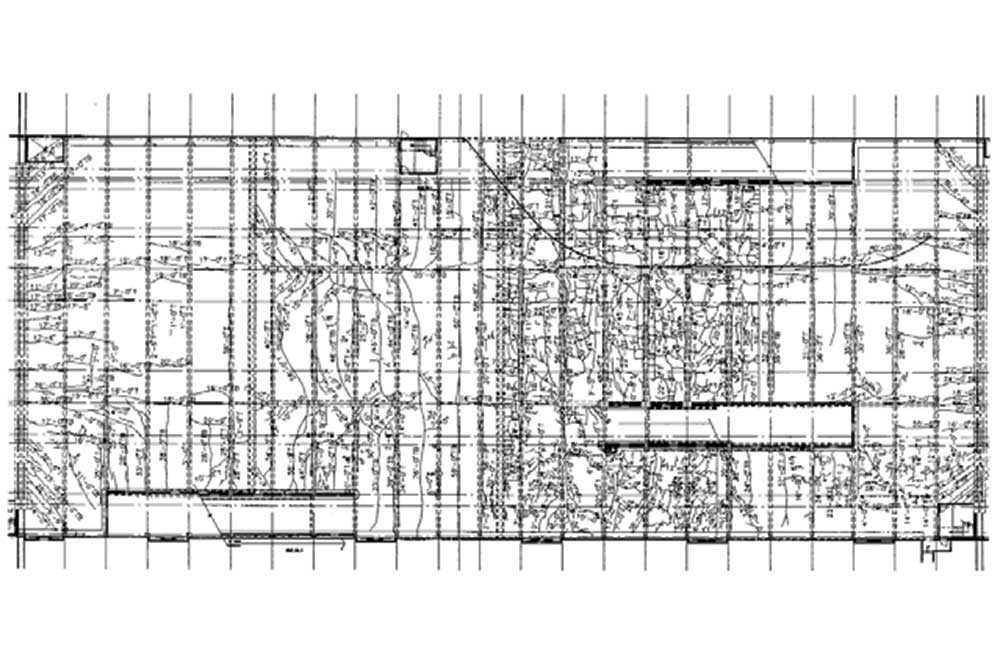

Parking structures A2 and B2 are free-standing buildings opposite the airport’s main terminal. Begun in the early 1990s, construction of Level 0, a below ground-level slab-on-grade, went smoothly. However, when slabs were poured for Level 1, they immediately began to crack severely. The 479,700 square feet of deck had approximately 70,000 linear feet of cracks, more than a foot of cracks for every seven square feet of deck. The cracks are not just surface cracks; many are visible from the underside where the deck forms the ceiling of Level 0.

To prevent a repetition of the cracks on the two levels yet to be built, airport authorities halted the project and sought new engineering expertise. They brought in Teng Li of Teng Li & Associates, Pasadena, CA, a structural engineer with a strong track record in parking structures.

Teng Li had recently had an experience which had a dramatic effect on his thinking about parking structures. He had served as demolition engineer for the California State University parking structure which had collapsed during the massive 1994 Northridge earthquake. That shock, measuring 6.9 on the Richter scale, brought down opposite ends of the Northridge building. The ends both collapsed inwards toward the center. Studying the CSU damage thoroughly brought Li to the surprising conclusion that the failure was rooted in shrinkage.

“Shrinkage had already utilized most of the stress resistance that was designed into the structure,” Li explains. “Due to shortening movements caused by shrinkage, creep, temperature changes and post-tensioning, residual stresses tend to build up in structures of large plan-dimensions like this. It is my opinion that residual stresses weaken structural strength. The shrinkage pulls on seismic resistance columns, which are then already stressed before any earthquake. The factor of safety is highly reduced. During an earthquake, the elements of a structure with the most built up residual stresses will tend to pick up the earthquake’s first shock. If this shock triggers a failure in that particular element, and the element’s ductility can’t compensate for the movement caused by the shock, then a local collapse will occur, and possibly be followed by a progressive collapse. Many structural failures during the Northridge earthquake can be traced back to residual stresses built up before the earthquake. Shrinkage was the main cause of that residual stress buildup. Initial shrinkage stress is most critical, and causes final failure.”

THE COURTSHIP

For Li, the challenge at John Wayne Airport was not merely to avoid unsightly cracks and the maintenance issues they cause. He was determined to reduce the residual stresses already built up in the existing structures.

He considered several options including:

Changing seismic-resisting systems

Introducing more delayed-closure strips (in order to reduce the size of the post-tensioned slabs)

Using shrinkage compensating concrete

“In considering all of the different alternatives,” says Li, “it was concluded that using shrinkage compensating concrete was the best approach for addressing both the issues of cracking and stress build-up.”

All concrete shrinks as it dries. However, unlike conventional portland cement concrete, shrinkage compensating concrete does not begin shrinking right away. During its first seven days, shrinkage compensating concrete actually expands. (See sidebar.) It attains sufficient compressive strength for post-tensioning while still in its expansion phase, providing a crack-free slab of high integrity when the tension is eventually applied.

Of course, this was not the first time shrinkage compensating concrete had been used with post-tensioning, not even its first application in parking structures. The technologies were combined in a variety of applications in the 1960’s and 70’s, including parking structures built in downtown Santa Monica, CA in 1968. Those structures feature slabs approximately 60 ft x 180 ft which are in excellent condition nearly 40 years after construction. In fact, Teng Li studied the Santa Monica structures while researching the solution for John Wayne Airport.

Use of Type K fell off sharply during the 1980’s, largely due to a marketplace anomaly: a general cement shortage reduced the economic advantage in manufacturing Type K, and most of the cement companies ceased production of it. Knowledge of the material and its utility virtually vanished from the construction industry. Today, the expansive component is available from CTS Cement Manufacturing Corp., Cypress, CA. The expansive component comprises 15-18% of the cement content; the rest is locally-available portland cement. Because it is such a small percentage of the total cement weight, the expansive component can be cost-effectively shipped virtually anywhere in North America.

By 1998, when the expansion of the John Wayne Airport parking structures began, there had not been a major post-tensioned Type K parking structure built in more than a decade. Teng Li had heard of the material though, and sensed its potential. He researched it thoroughly and concluded it was the ideal solution for the challenges before him.

Li’s proposal was to increase the number of individual post-tensioned slabs on each deck, resulting in slabs 175 feet long, and varying in width from approximately 85 feet to 105 feet. The slabs were designed to use shrink-age compensating concrete, and be post-tensioned when the concrete reached a specified strength, typically achieved after three or four days. Li believed the two technologies were a good match because the concrete would still be expanding when post-tensioning was applied, so there would be no shrinkage-induced stresses before tensioning. Post-tensioning would then induce permanent compression, which would avoid the buildup of tensile stresses and give additional insurance against cracking afterwards.

THE WEDDING

There is hardly ever a wedding that goes off exactly as planned, and real-world construction is somewhat similar. The work was done during the summer of 1998, a season that tested the materials to their limits. Record high day-time temperatures reached triple digits. Because of low humidity in the region, daytime heat is not retained well by the atmosphere, and nighttime temperatures may drop 20 or 30 degrees. Such large temperature changes traditionally pose risks for fresh concrete. Surprisingly, there was also rain that year, a meteorological anomaly in a Southern California summer.

The 46 slabs comprise 20,000 cubic yards of concrete. Due to airport traffic regulations, all the pours had to be done at night. This was actually good for the project, since temperatures below 90ºF are recommended for pouring Type K concrete. Teng Li believes that the lower temperatures of night-time pouring are generally better for concrete. This idea is supported in data reported by the U.S. Department of the Interior, which shows that lower initial casting temperatures result in concrete with higher final compressive strength.1 The slabs were moist-cured using wet burlap.

Construction on Structure B-2 encountered a few problems: for example, a bad finish due to rain on Level 3 had to be refinished with special cement. This area is easily identifiable by a surface crazing pattern which is not found on any of the Type K surfaces. Generally, however, the pour went well. Unlike the ill-fated original level, the new slabs did not crack.

THE STATE OF THE UNION

As of this time, there is no direct evidence whether or not the combination of technologies achieved the engineering goal of reducing residual stresses in the structure; fortunately, Southern California has not experienced a major earthquake since the structures were built. However, the goal of minimizing cracking can be readily assessed, and it may be suggestive of the level of stress-reduction that was achieved.

The structure was inspected five years after pouring, and showed no drying-shrinkage cracking. This stands in stark contrast to not only the extensively cracked decks of Level 1, but also the normally cracked decks of the other two structures in the airport, A-1 & B-1.

Today, nine years after construction, the concrete remains in remarkably good condition. The surfaces of the decks look fresh, the troweled texturing still crisp.

“With shrinkage compensating concrete,” comments Teng Li, “the surface is as strong as the concrete in the interior of the slab. With conventional concrete, the surface becomes weak.” In conventional concrete, bleed water concentrates soft fines and laitance at the surface during finishing. It also raises the water/cement ratio at the surface, locally lowering compressive strength, which translates into reduced abrasion resistance.

Type K concrete has a stronger surface due to its high water-demand. It yields minimal bleed water, so it does not suffer from these weakening processes. The surface retains the full hardness of the mix. ACI 223 – Standard Practice for the Use of Shrinkage Compensating Concrete notes, “Shrinkage-compensating concrete, when properly pro-portioned and cured, has an abrasion resistance from 30 to 40 percent higher than portland cement concrete of com-parable mix proportions.”2

Teng Li expects, “It will look exactly the same in 40 years. I don’t see any material that can compete with it.”

FOR BETTER OR FOR WORSE

Is it a perfect marriage? No, there are no perfect solutions because there are never perfect conditions. Engineering cannot control sudden gusts of wind, mixing trucks stalled in traffic, the superiority of one finisher over another, or any of the other myriad variations that can occur during construction.

Is it a successful marriage? The owner says Yes. “It worked successfully,” summarizes airport spokesperson Wedge. “We’re pleased with the results.”

Teng Li credits the Type K concrete. “From a structural point of view, there’s no other material that can compare. For such large slabs, you need something to prevent shrinkage. The shrinkage problems caused by other types of cement can be avoided by choosing shrinkage compensating concrete. In my opinion as a structural engineer, it should be used in lieu of them.”

In considering the overall project, his assessment seems tinged with something like parental pride: “It’s beautiful.”

REFERENCES

1 CONCRETE MANUAL – A Water Resources Technical Publication, US Dept. of the Interior Bureau of Reclamation, p 26 figure 11, Eighth Edition 1975

2 ACI 223-98 section 2.5.7: “ACI 223 1970; Nagataki and Yoneyama, 1973; Klieger and Greening, 1969”

Photos by Steven H. Miler, courtesy of CTS Cement unless otherwise noted.

© Copyright 2007, Chusid Associates. First serial rights and a non-exclusive right to reprint are offered to PTI Journal in accordance with terms of correspondence.

Written by: Michael Chusid, RA FCSI. Michael Chusid is an architect, a Fellow of the Construction Specifications Institute, and an ACI member. His company, Chusid Associates, provides technical and marketing consulting services to building product manufacturers. He can be reached at www.chusid.com.

CTS Cement Manufacturing Corp. is the leading manufacturer of advanced calcium sulfoaluminate (CSA) cement technology in the United States. Our Komponent® and Rapid Set® product lines are renowned for proven performance, high quality, and exceptional service life. Contact CTS Cement for support on your next project.

Call 1-800-929-3030.

Original publication: Chusid, M., RA FCSI. (2007, July). A Perfect Match: Post Tensioning and Shrinkage Compensating Concrete Form a Durable Union at John Wayne Airport. PTI Journal, 77-82.

HOW SHRINKAGE COMPENSATING CONCRETE ELIMINATES CRACKING

Drying shrinkage cracking occurs because concrete is weak in tension.

When concrete dries, it shrinks. If it is externally restrained from shrinking freely (for instance, by a slab experiencing friction with its subgrade) tensile stress is induced within the concrete. When stress exceeds the concrete’s tensile strength, cracking begins. Drying shrinkage usually occurs when concrete is relatively new and its strength is at its lowest. Control joints are cut into concrete slabs to relieve stress by encouraging cracks along neat, straight, evenly-spaced lines.

Shrinkage compensating concrete is made using Type K cement, which includes an expansive hydraulic cement. The concrete expands during its first seven days of wet curing, then begins to shrink as it dries. Expansion effectively nullifies subsequent shrinkage. For instance, the vast majority of test samples from the John Wayne Airport project, after 35 days of air drying, experienced a net expansion of up to 0.075%. A few samples showed a net shrinkage, generally less than -0.01%. Conventional concrete may experience net shrinkage of –0.04% for more, depending on the w/c ratio.

Type K concrete is usually internally restrained, either by steel reinforcing bars or by synthetic fibers blended into the mix. Expansion puts the restraint into tension, which in turn puts the concrete into compression. Concrete is strong in compression. Subsequent shrinkage relieves the compressive stress, but does not induce tensile stresses that would cause cracking. Post-tensioning applies restraint externally, but the compressive effect is similar, and cracking is eliminated.