| CRCP (continually reinforced concrete pavement) | DOT Cement, Low-P™ Cement, Rapid Set® Cement, Komponent®, Liquid Low-P™, Low-P™ FA1 Cement |

| DBR (dowel bar retrofit) | DOT Repair Mix |

| JPCP (jointed plain concrete pavement) | DOT Cement, Rapid Set® Cement |

| LCB (lean concrete base) | Rapid Set® Cement |

| Municipal Work (Bus pads, sidewalks) | DOT Cement, Komponent®, Liquid Low-P™, Rapid Set® Cement |

| Repair and rehabilitation | Asphalt Repair Mix, Asphalt Resurfacer, Cement All®, Concrete Mix, DOT Cement, DOT Concrete Mix, FPP Concrete Mix, Liquid Low-P™, Rapid Set® Cement, UHPC Mortar |

The Missouri I-35 pavement rehabilitation project proved that Rapid Set® Cement can be successfully produced and placed using a conventional ready mix plant—dispelling the common concern that the material sets too quickly for drum truck delivery.

More stringent performance requirements combined with changes in type, quality, and availability of concreting materials is inspiring innovation, creativity, and collaboration. It is also renewing interest in materials with established, proven performance that offer solutions to today’s challenges. One of those experiencing an inspiring renaissance is Type K cement.

The tire studs and chains that are popular with Pacific Northwest drivers carve troughs into concrete. A regional contractor and Washington State pavement engineers are watching how fast-setting, ultra high-strength Rapid Set® UHPC Mortar stands up to traffic.

Broken continuous reinforced concrete pavement (CRCP) panels were replaced using Rapid Set Cement and local aggregates. The repaired pavement reached a flexural strength of 400 psi in four hours and reopened to traffic by 6:30 am each day.

Rapid Strength Concrete (RSC) slabs on six California jointed plain concrete pavement (JPCP) highway projects were surveyed. The overall performance of the RSC slabs were similar and considered to be outstanding over 13 years.

Rapid Strength Concrete (RSC) slabs on six California jointed plain concrete pavement (JPCP) highway projects were surveyed. The overall performance of the RSC slabs were similar and considered to be outstanding over 13 years.

Work was performed in temperatures from 18° to 49° degrees Fahrenheit. Rapid Set® DOT Cement’s high early strengths allowed the concrete to be exposed to freezing temperatures that portland cement concrete typically can’t handle.

The I-64/40 pavement patching project consisted of replacing 7,500 square yards of 11-inch-thick concrete panels. Work was completed ahead of schedule using Rapid Set Cement.

To ensure all timelines and incentives could be met, Rapid Set Cement and DOT Repair Mix Concentrate (aka DOT Concentrate) were used for all patching and doweling work. Work included full-depth panel replacements and slot stitching at longitudinal cracks and joints and DBR at transverse cracks and joints using DOT Concentrate.

Mining has driven Utah's growth since before the territory became a state in 1896. Maintaining 24/7/365 access to these facilities is therefore critical to the state's economy. To keep traffic moving when the north-south route through one mining town required repair, the state chose to use ASTM C1600 very-rapid-hardening Rapid Set® Cement.

The North Carolina Department of Transportation (NCDOT) has used concrete mix designs containing Rapid Set Cement since 2014 to meet performance specifications for their roadway panel replacement projects. Here, the contractor was able to meet the required reopening strength before 6:30 am every day in every season.

Because the roadway had to be returned to traffic by a specified time with a minimum compressive strength of 1600 psi, Rapid Set® Cement’s fast curing time was the ideal solution. The contractor was able to replace more broken pavement panels each weekend.

When the highway has to be repaired and reopened by 6 a.m. and the pavement has to have 3000 psi compressive strength to reopen, the Washington State DOT (WSDOT) often specifies Rapid Set Cement. Contractors working for the agency placed 200 tons over three months to restore a smooth ride for commuters.

Engineering firms URS and Stantec received an Honor Award for their innovative way of designing pavement with minimal joints, no curling, no cracking, and no spalling. Komponent shrinkage-compensating concrete was used for the skid pad.

After removing the concrete around the manholes, the collars were reset to the correct elevations using Concrete Mix. SET Control was used when temperatures rose. With no delays, crews met the construction schedule.

El Paso, Texas, in summer is hot. Here’s how Synergy Construction’s crews extended the working time of Rapid Set® as they repaired and/or replaced reinforced concrete panels on almost 200 miles of road in temperatures up to 109 degrees Fahrenheit.

Approximately 7 to 8 miles of freeway needed potholes repaired. Concrete Mix was chosen for its high early strength so repairs could be made overnight. The lanes were successfully open for traffic each morning.

Copings at train station were repaired to provide a safe surface for embarking/disembarking passengers. Work was performed during hot weather with temperatures reaching 95 degrees Fahrenheit. Cement All and SET Control were used.

Salt Lake City’s micro-trenching work occurred when Utah was still experiencing winter weather. Flowable Fill flowed well into the trench’s small space and set up quickly despite the cold weather, achieving the specified requirement of 500 psi in 28 days, with half the maximum strength at opening, which was a few hours.

The Utah DOT uses bulk Rapid Set Cement on time-sensitive projects to minimize inconvenience to the driving public. Contractor Dry Creek Structures consistently met the 6 am reopening deadline and 4000 psi (compressive) reopening strength. Demolition, installation, and curing of the newly placed concrete was completed in time for the morning commute.

Portions of two busy interstates had to patched overnight and reopened to traffic by 5 am. Using Rapid Set Cement, contractor RA Knapp Construction was able to get 2.3 times the production in the same eight-hour time frame. The Kansas DOT has added Rapid Set to its patching specifications.

The NCDOT oversaw the full-depth panel replacement on the southern stretch of Interstate-40 in Raleigh, North Carolina. Rapid Set cement concrete was used and met the specifications of 400-psi flexural strength in two hours, in half the time.

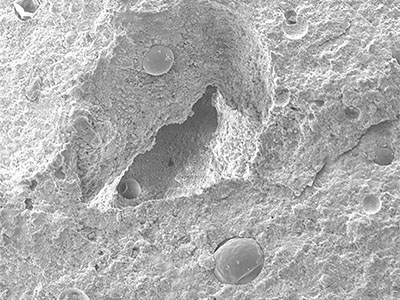

Unlike the chemically stabilized air bubble of traditional methods, Low-P MSA's air voids are made up of tiny, flexible hollow polymer spheres that act as microscopic forms in the cement matrix. They are rigid enough to form voids in the hardened concrete, yet soft enough to compress and allow space for expanding water to provide the desired freeze/thaw protection.

Work was able to be performed overnight and lanes reopened to traffic by morning. 12,000 spall repairs and dowel bar retrofits were completed using DOT Repair Mix.

300 cubic yards of concrete were successful placed in 6 hours. The freeway opened to traffic an hour after placement. Short Load produced the Rapid Set Concrete.

Using a fast-setting Rapid Set Cement for a Latex Modified Concrete Overlay instead of Type III portland cement, allowed schedules to be met despite unexpected delays.

Rapid-hardening cement concrete can be used anywhere portland cement concrete can be used, and offers the greatest advantages when used for repair or rehabilitation of highway and airport pavements, bridge decks and overlays, and other projects where time is of the essence. Product used is Rapid Set Cement.

The sustainability of concrete, the most widely used material in the world, is still a difficult concept to quantify. However, the Product Category Rules (PCRs) for concrete are a step in the right direction. This article focuses on the sustainability of materials used in civil infrastructure such as highways and bridges, but the concepts explored are also frequently applicable to materials used for building repair.

Volumetric Mixer produces 398 cubic yards of rapid strength concrete in just 5 hours, for panel replacement work on one of California's busiest freeways. Product used was Rapid Set Cement.

Asphalt has held the lion’s share of repair work for years. But now, pavements made of concrete prove to be more cost effective in the initial installment as well as more durable than asphalt, making them the ideal choice for repairing aging roadways. Product used is Rapid Set Cement.