| Polished slabs-on-ground | Komponent®, System-K™ |

| Polished toppings | TRU® Self-Leveling, TRU® PC, TRU® SP |

| Repairs, Patching (Trowel Grade) | Cement All®, Concrete Mix, Mortar Mix Plus, CR Concrete Resurfacer, UHPC Mortar, V/O Repair Mix |

Oklahoma City concrete flooring specialists Thomas and Josh Owens used six Rapid Set® products to repair and finish 22,000 square feet of cracked and uneven slab – Owens Concrete Staining’s largest installation of TRU® SP polished concrete topping.

Remodeling at the corporate office of the world’s largest bank provides a textbook example of why project owners and contractors choose Rapid Set® self-leveling polishable overlays: fast turnaround and a beautiful aesthetic. Award-winning commercial flooring contractor RD Weis installed this TRU® SP floor in less than a week.

When Hardy World LLC developed two old buildings in downtown Pittsburgh into a single residential community, new tenants were allowed to choose from several finishing flooring. Four chose polished concrete. Instead of polishing portland cement concrete, Wexford Contracting installed fast-setting TRU® PC, an architectural topping with aggregate that looks like polished concrete but can be ground wet or dry and polished in 24 hours.

Multipurpose portland cement-based CTS 24/6 Concrete Mix is a versatile repair material for applications where rapid strength gain and high ultimate strength are desired. Flooring specialist Surface Solutions placed and polished almost 3,000 square feet for a global consulting firm.

When renovating its Manhattan headquarters, the National Basketball Association sought an aesthetically pleasing and durable walking surface that would reflect its status as one of North America’s four major professional sports leagues. Rapid Set® TRU® PC’s outstanding clarity and gloss is reflecting well on the organization.

American fast casual restaurant committed to eco-friendly construction chooses eco-friendly TRU® PC polished concrete floor made with Rapid Set® calcium sulfoaluminate (CSA) cement, which emits about a third less carbon dioxide during manufacturing than portland cement. Other Rapid Set® products used were Acrylic Primer, LevelFlor® and TXP™ epoxy primer.

When the National Hockey League (NHL) moved across town to new headquarters at New York City’s One Manhattan West Class A office tower, the league chose TRU® SP flooring for offices and a street-level store. Formulated with low-shrink, long-lasting Rapid Set® calcium sulfoaluminate (CSA) cement, the self-leveling topping is a sustainable flooring choice that reflects the building developer’s award-winning emphasis on sustainable construction materials.

When high-end clothing retailer expanded its store near Rockefeller Center in Manhattan, All Stone Restoration used Cement All® repair material to fill in damage to the old concrete substrate; coated the surface with TXP Fast epoxy primer; and mixed and placed more than 800 60-pound bags of TRU® PC polishable topping to restore the old floor and fashion two sets of stairs connected by a landing.

A self-leveling flooring product that mimics polished concrete when ground and polished, TRU® Self-Leveling in Natural complements the wood and tile accents in a residential tower built along the East River in Brooklyn. Contractor Prep-Crete installed and finished 14,000 square feet in the elevator lobbies.

The Smile is an award-winning curved apartment building in Harlem that incorporates a building that was already on the site. Before final flooring could be placed, M.O.G. Contracting used 125 tons of Rapid Set® LevelFlor self-leveling underlayment to level out the existing concrete substrate.

First Tower Bank in downtown Austin, Texas, was the first high-rise building built after 9/11. Almost two decades later, national flooring contractor ModernCrete used 23 pallets of TRU® SP polishable topping to quickly repair and restore the building’s 33 concrete floors.

The Houston office of international professional services firm Deloitte wanted its damaged, uneven floor to project the firm’s high-end services. Houston-based flooring contractor Johnson & Sons used Rapid Set® TXP™ Fast Epoxy Primer to level and prime the surface before installing cement-based Rapid Set® TRU® SP (for “salt and pepper”) polishable topping.

National decorative flooring contractor ModernCrete Concrete Design added another marquee name to its client list when it installed 13,000 sq ft of Rapid Set® LevelFlor® self-leveling underlayment topped with Rapid Set® TRU® SP Natural polishable overlay for the Austin Marriott Downtown lobby.

Faced with concrete too damaged to polish, the new owner of a furniture showroom replaced the 2,000-square-foot entryway floor with TRU® PC polishable topping.

When the Villegas MD Ophthalmology Clinic in Puerto Rico decided to expand, San Juan-based Cadyth Contractors repaired surface imperfections with Rapid Set® Cement All® before installing Rapid Set® TRU® Self-Leveling architectural topping to match the existing floor to the new floor.

An award-winning Chicago flooring contractor used TRU(R) PC self-leveling overlay to restore two of United Airline's 19 floors in North America's third-tallest building. The general contractor was so pleased with the result that Menconi won the contract for restoring the remaining 17 floors.

Konchan Polishing demonstrates the art of quickly delivering beautiful and durable floors for less than half the cost and installation time of terrazzo. The contractor installed Rapid Set® TRU® Self-Leveling polishable floor topping seeded with decorative aggregate at Mike Erdman Auto Group's new location.

TRU PC and TXP Fast Epoxy Primer were used at American Eagle Outfitters' design center and retail location. The floors were polished to an 800-grit finish.

Clean, uninterrupted lines carry into the Tesla store and cars are showcased on a polished concrete floor. TXP Fast Epoxy Primer, TRU Self-Leveling, and a TRU Self-Leveling Spiked Roller were used.

Polished concrete flooring continues to be in demand for today’s retail environment. To meet the design needs, TRU PC Polished Concrete was chosen to be used as the overlay. TXP Fast Epoxy Primer and TRU PC Spiked Roller were also used.

For the polished concrete flooring in the atrium of the student union building TXP Fast was used to prime the substrate. Then TRU Self-Leveling with a light gray integral color was installed.

Tesla built their showroom and service center in the Meatpacking District next to the popular High Line park, making the location a highly visible one. TRU Self-Leveling Gray, TXP Fast Epoxy Primer, TRU Self-Leveling Spiked Roller were used to create the high-gloss concrete floors.

TXP Fast Epoxy Primer, TRU Self-Leveling Gray, and TRU Self-Leveling Spiked Roller were used as the architectural flooring at the Kato Road location at Tesla's Manufacturing Facility.

In 2018, the University of North Texas Health Science Center (UNTHSC) in Fort Worth began rolling out a master plan to add 2 million square feet of space to the 34-acre campus. This building received two TRU® polishable overlays after the substrate was primed with no-VOC TXP™ Fast Epoxy Primer to promote penetration and adhesion.

The showroom's aging floor needed a facelift. TRU PC provided high strength and durability, and achieved the desired glossy appearance. TXP Fast Epoxy Primer and TRU PC Spiked Roller were also used.

The crew was able to overlay an older floor to make it look like new with TXP Fast Epoxy Primer, TRU PC, and TRU PC Spiked Roller were used. The TRU PC overlay was polished in 1 day.

120,000 sq ft of polishable concrete overlay was installed in the Walmart Supercenter. TRU® PC Polished Concrete, TXP™ Fast Epoxy Primer, and TRU® PC Spike Roller were used.

As part of the 5,000 sq ft renovation of uneven concrete flooring, providing a polished finish in under a week, and matching the new flooring to the existing polished concrete slab, TXP Fast Epoxy Primer and TRU Gray Self-Leveling were used.

The atrium floor is embellished with a large UC Bearcats logo. LevelFlor was used as the underlayment and TXP Fast Epoxy Primer, TRU PC, TRU Self-Leveling, and TRU PC Spiked Rollers were used to create the polished concrete overlay.

In the world of concrete overlays, it’s what lies beneath that matters most. Proper preparation is critical to the long-term success of any concrete overlayment.

During the store remodel, workers had to perform extensive surface prep prior to the TRU installation. Cement All was used for the repairs and TRU Self-Leveling with integral colors were used as the polished concrete overay. The final surface was polished to an 800 grit and sealed.

Cement All, Concrete Mix and LevelFlor were used to restore the existing floors and create a smooth surface. TXP Fast Epoxy Primer, TRU Self-Leveling, and TRU Self-Leveling Spiked Rollers were used to create the polished concrete overlay.

This Target store features stenciled concrete floors that lend a modern look to the space. Acrylic Primer, LevelFlor, TXP Fast Epoxy Primer, TRU PC Polished Concrete and TRU PC Spiked Roller were used.

The floors of Gucci's offices and showroom were renovated by first leveling the surface, then installing a polished concrete overlay. Rapid Set® Acrylic Primer, Cement All®, LevelFlor®, TRU® PC Polished Concrete, and TRU® PC Spike Roller were used.

The floor of a lobby that has a high volume of traffic was first leveled from 1/4 inch to 2 inches and then polished and stained. Products used were Rapid Set® Acrylic Primer, LevelFlor®, TXP® Fast Epoxy Primer, and TRU® Self-Leveling.

The project owner wanted the building’s walls and floors to look like exposed concrete. Skim Coat was used as the underlayment to level and smooth the concrete substrate. 40,000 square feet of polished concrete overlay in the entrance and lobby were installed with TRU Self-Leveling. Gray pigment was added to match the flooring to the walls.

The flooring of the newly purchased space needed to be rehabbed to match both the higher elevation and the polished finish of the restaurant’s existing concrete floor. Concrete Mix, Concrete Leveler and TRU Self-Leveling were used. By using Rapid Set products, polished concrete flooring was able to be installed in less than a week’s time.

NASA wanted an easy to maintain floor that would withstand the test of time. Work was completed in 5,000 square foot sections to keep part of the cafeteria opened during the day. TXP Fast Epoxy Primer, TRU PC Polished Concrete and TRU PC Spiked Roller were used.

TRU Self-Leveling was applied at about 3,000 square feet per hour, with two crews working back-to-back 12-hour shifts. Prior to TRU, TXP Fast Epoxy Primer was applied at 24 mils on the profiled substrate.

Nearly 54,000 sq ft of stained, polished concrete overlay was installed in two retail locations. Acrylic Primer and LevelFlor were used to level the substrate in one location. TXP Fast and TRU PC were used in both locations to create the polished concrete overlay. Grinding started the next day in both jobs.

An integral colored, polishable concrete topping was installed in the restrooms of the Cincinnati Music Hall. TXP Fast Epoxy Primer was used followed by TRU Self-Leveling Natural with integral color. The crew diamond-polished the floor to a 400-grit finish.

The expansion and renovation work included replacing the tile flooring in parts of the church with a polishable concrete overlay for a high-sheen, salt-and-pepper finish. TXP Fast was applied first. Then TRU Self-Leveling Natural and TRU Self-Leveling Gray were blended together and mixed with fine aggregate. The TRU was polished to a 1,500-grit finish.

This retail project called for 12,000 square feet of polished concrete flooring. After priming with TXP Fast, contractor CCI Flooring installed TRU PC at 1/2-inch thickness. Grinding was able to start the next day. The crew diamond-polished the floor to an 800-grit medium-sheen finish.

Build-out of the new Burlington Coat Factory included replacing two levels of uneven concrete flooring with a polishable concrete overlay. TXP Fast Epoxy Primer, TRU Gray and TRU Self-Leveling Spiked Roller were used on 25,000 sq ft of flooring.

Cement All was used to patch the substrate before performing surface prep. To prevent pinholes and create a strong adhesive grip for the topping, TXP Fast Epoxy Primer was used. TRU Self-Leveling with integral coloring was used as the topping. To make sure the TRU did not set too fast in the heat, SET Control was added to the mix.

Blue C Sushi wanted an integrally colored black polished concrete floor in their new restaurant. Cement All was used to patch the substrate before performing surface prep. TXP Fast Epoxy Primer was used to prevent pinholes and create a strong adhesive grip for the topping. Then TRU Self-Leveling with black integral color was placed at 3/8 inch thick.

TXP Fast Epoxy Primer was used to prevent pinholes and create a strong adhesive grip for the overlay. Then Hippo Mixers were used to mix TRU PC with dye to match the company's branded color. The overlay was poured in 5,000 square-foot sections at 3/8 inch thick while the store remained open throughout the project.

Amazon's corporate office wanted to upgrade the elevator landings of its multi-floor office space. At each landing, TXP Epoxy Primer and TRU Self-Leveling were used. As a final decorative and functional touch, the corresponding floor numbers were stenciled on each landing.

The build-out of Amazon's new office space called for polished concrete floors on the fifth floor and the 22nd floor, for a total of 10,000 square feet. TXP Epoxy Primer was applied to the substrate first, followed by TRU PC. The TRU PC Spiked Roller was also used.

When one of the world's largest hotel chains turned an old bank building into a hip new property, the old concrete floor was restored using a CTS Cement polished concrete flooring system. Rapid Set® Acrylic Primer and LevelFlor® were used as the underlayment. TXP™ Fast Epoxy Primer and TRU® Self-Leveling were used to create the polished concrete overlay.

The foundation of the main lobby in this office space was leveled with LevelFlor, then TXP Fast Epoxy Primer and TRU Self-Leveling were used to create the polished concrete overlay.

The University of Cincinnati renovated the 1819 Innovation Hub. LevelFlor, TRU PC, and TRU Self-Leveling were used to renovate the 40,000 sq ft floor.

Contractors often face challenges when asked to produce a uniform appearance in a polished concrete overlay. To achieve consistency in each project, here are the three necessary steps to take before grinding and polishing.

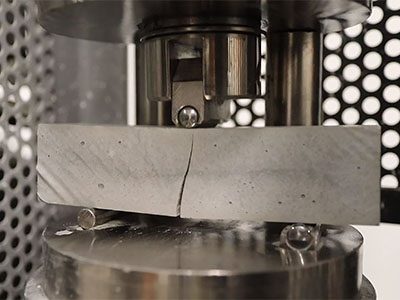

To ensure decorative overlayments achieve performance and aesthetic expectations, compressive, tensile and flexural strengths must be evaluated as a whole. Together, they provide a more comprehensive analysis of overall performance. This approach help architects and specifiers meet and exceed performance and aesthetic expectations in polished overlay designs.

After renowned architect Norman Foster was asked to lead the expansion and renovation of the famed Norton Museum of Art in West Palm, he wanted a high quality seamless concrete floor. Because of the excellent results Kemiko Concrete System achieved with Rapid Set TXP Fast, LevelFlor, and TRU SP, they received an award of excellence from the museum owner.

University of Cincinnati Arena upgrades concrete flooring, multiple concourse levels, locker rooms, restrooms, and underneath the wood basketball floor. Products used were TRU PC and TXP Epoxy Primer.

By using fast-setting materials to speed installation time and choosing colored glass as the embedded aggregates instead of pricier materials, like marble chips, D.J. Rosetti was able to provide the owner with a strong, attractive and budget-friendly terrazzo flooring option. Products used include TRU Self-Leveling, TRU Self-Leveling Spiked Roller, and TXP Fast Epoxy Primer.

Tri-State Underlayments/Franz Floors only had four days to restore 1,200 sq ft of the existing flooring before interior framing began. For this reason, the contractor chose to use Rapid Set cement products to install the flooring, because they set quickly to produce 3,000 psi in one hour and full strength of 8,000 psi in one day. Products used include Concrete Mix, FLOW Control, SET Control, TXP Primer, TRU Self-Leveling.

The project’s scope included 9,000 square feet of concrete overlay and resurfacing both indoors and outdoors for walkways, hallways and more. A non-porous, cementitious surface was required, and the crew was working against a tight timeframe to completion. Products used include Acrylic Primer and TRU Self-Leveling.

The build-out of Michaels included replacing 18,900 sq ft of cracked, uneven flooring with polished concrete. It took two weeks to complete surface prep, the overlay application and polishing, which was almost three times faster than tearing out the floor and replacing it. Products used include TRU PC and TXP Fast Epoxy Primer.

Home Depot needed a showroom floor in a short amount of time. This fast-track project used fast-setting products to transform an old, wavy concrete slab into high-sheen flooring. The project team used a high performance cementitious topping that could be easily polished to a high sheen. Products used include TRU PC and TXP Epoxy Primer.

12,000 sq ft of floors in common spaces, corridors, and the lobby were polished and decorated with a colorful block pattern. By the project’s end, the contractors and design team were able to come under budget with beautiful results and students at the new elementary school will be able to enjoy a creative, collaborative learning environment. Products used include TRU Self-Leveling, TRU Self-Leveling Spiked Roller, and TXP Fast Epoxy Primer.

Calcium sulfoaluminate (CSA) cement products have provided architects and contractors with the ability to produce beautiful flat, polished floors in a fraction of the time, with considerably less expense than using portland-cement based concrete and constructing entirely new floors.

The decorative options available with a polishable cementitious overlay turns a damaged, ugly floor into a completely different surface. The overlay offers an easy solution to make the floor designable, for both decorative and functional effects.

Concrete Visions uses mirrored-glass aggregate to create a polished concrete overlay that mimics a winter wonder every day of the year. Product used was TRU Self-Leveling.

Thin coatings that can be polished work wonders on floors new and old. But applying them right takes know-how.

Three projects illustrate Calcium Sulfoaluminate (CSA) cement-based products are highly effective materials to use when needing to meet aggressive timetables, reduce costs and achieve high quality results. These materials have far more rapid set times than portland cement, and allow for a range of architectural touches and decorative finishes, including colored and polished overlays. Product used is TRU Self-Leveling.

The owner requested a decorative design be added to the polished concrete floor surface. The chosen design was a display of roses with angel wings embracing the long stems. The mural was scored into the floor and the 3-D effect was brought to life with varying dyes and pigments. Product used was TRU Self-Leveling.

One of many reasons polished concrete toppings are popular as a finished floor system for both damaged floors and new construction is customers want polished concrete without all the flaws showing up in the finished floor. Placing and polishing a concrete overlay requires a great deal of attention and more coordination than polishing an existing slab. Here are a few tips when taking on an overlay-polishing job.

The extensive amount of repairs required to meet JCP’s expectations will strengthen the industry and keep expectations high when it comes to polished concrete. Product used was TRU Self-Leveling.