In harsh weather conditions, using portland cement plaster can be problematic and expensive. Rapid-setting plaster based on calcium aluminosulfate (cas) cement can be a viable alternative, enabling design professionals to attain the traditional beauty and durability of a genuine plaster finish.

The authors know of a project that was small but crucially located – it involved exterior plastering on the fascia over the eight entryways to Thompson Junior High School in Oswego, Illinois. Unlike a simple wall, which can be tied up for several days on end without inconveniencing or endangering people, some entryways must remain accessible at all times to ensure normal building function and life safety. Consequently, the location’s criticality restricted the work schedule.

Additionally, the school required plasterers to work around its schedule, putting up scaffolding after classes began and removing it before students left at 3 p.m. Under temperate weather conditions, this would require setting up and taking down the scaffolding three times – once each for the scratch, brown, and finish coats.

As it was January, weather was far from temperate. During the day, the unseasonably warm 5 to 7-C (40 to 45-F) conditions did not present an obstacle to applying the plaster. However, the nighttime temperature drop could have interfered with curing, which would necessitate tenting the application and keeping it heated for up to three days after scratch coating, and again, after brown coating. In addition to conflicting with school access, this situation could dramatically increase project costs.

The contractor, J.P. Phillips Plastering, solved both time and temperature problems with a rapid-setting plaster that cures within 150 minutes and achieves a high percentage of its ultimate strength within a few hours.

Scaffolding was erected on two entryways at a time, leaving adequate unblocked entries for safe egress in emergencies. The plaster cured fast enough to enable scratch and brown coats to be applied in a single day, with enough time to still remove the scaffolding before school dismissal. The plaster had cured sufficiently during the day, eliminating the need for overnight heating. After the scaffolding had been re-erected the following day, the finish coat was applied, completing the job.

Although this project was small, it faced many difficulties encountered on larger projects with exterior portland cement plaster in extreme weather conditions. In cold, wet, or hot-and-dry weather, plaster materials based on portland cement (including plastic cement) must be protected from the elements. These protective measures can spike costs and delay schedules. The quality of the result may also be compromised by a higher degree of drying shrinkage cracking than usual. Consequently, the practice of plastering as a building envelope – despite its status as a traditional solution – has been severely curtailed in many parts of North America.

These difficulties led to a rise in exterior insulation and finish system (EIFS) applications in the country. However, the widespread incorrect installation of EIFS resulted in water intrusion issues. Product standards were altered to mitigate problems, but the large number of EIFS lawsuits has reduced it use. In many places, the material is effectively unavailable for residential projects because contractors cannot get liability insurance for it; however, it is still applied on commercial projects.

Design professionals can still obtain the benefits of a genuine plaster finish by using rapid-setting plaster based on calcium aluminosulfate cement. This alternative form of cement minimizes or eliminates many problems and expenses associated with portland cement plaster in adverse conditions.

The increased speed of finishing the job with rapid-setting cement can create additional savings – other trades can proceed with exterior work, sometimes three or four weeks sooner than possible with conventional plaster. Additionally, as a breathable finish, it allows moisture to escape, which helps avoid the problems of mold and rot associated with wetness trapped behind EIFS. Indeed, rapid-setting plaster’s properties make the beauty and versatility of plaster a practical option under a wide variety of conditions.

The difference in plasters

CAS plaster contains a combination of calcium aluminosulfate and the usual calcium silicate hydrates (CSH) found in portland cement. The plaster gains strength much more quickly than portland cement plaster, attaining initial set in 90 minutes and final set within 150.1 In testing, CAS plaster achieved 23,973 kps (3477 psi) compressive strength in seven days (193 percent of the code minimum), and 29,647 kps (4300 psi) in 28 days (148 percent of code minimum). It also tested to have about twice the impact resistance of typical portland cement plasters,2 a valuable property in abuse-prone applications such as school buildings. EIFS is far more vulnerable to impact than either plaster system.

Rapid-setting plaster differs markedly from portland cement plaster in terms of drying shrinkage. The latter contains a high percentage of excess water, included to make the mix workable. Water not utilized in the chemical reaction of hydration must evaporate afterward, which decreases the volume of the hardened plaster. This shrinkage often begins before the plaster has cured and gained strength. The plaster is restrained from shrinking freely because it is hardened around lathing – this results in internal tensile stress that exceeds the plaster’s rather low tensile strength, causing drying shrinkage cracks.

Rapid-setting plaster shrinks little, if at all. It has been described as ‘thirsty’ because it uses almost all its mix water. With practically no excess water to evaporate, there is minimal shrinkage, providing resistance to drying shrinkage cracking. Portland cement plaster must be allowed long moist-curing times to gain strength before shrinkage occurs.3 This necessity draws out the time plastering scaffolding and materials occupy the jobsite, often obstructing other work.

In contrast, rapid-setting plaster cures in less than three hours, allowing two coats to be applied in a single day. Application is completed without long delays for curing, freeing up the site more quickly.

The cold, hard facts

Cold weather application of exterior portland cement plaster presents expensive obstacles and exacerbates subsequent problems with cracking. Like most chemical reactions, cement hydration occurs more slowly at low temperatures. Portland cement plaster may take eight hours to achieve initial set at 4 C (40 F). Timing of each successive operation of plaster application is delayed while the plasterer waits—a ‘four-hour’ job can take eight hours.

Nightfall is frequently accompanied by a drop in temperature, while plaster is still in the earliest stages of hardening. According to ASTM C 926, Standard Specification for the Application of Portland Cement-based Plaster, ambient temperature for plaster application must be 4 C or above, and plaster must be prevented from freezing for at least 24 hours after set.4 The usual method of preventing freezing is to tent the wall with plastic sheeting and run heaters underneath. In climates where winter temperatures are below 4 C for weeks, there must be constant heating before, during, and after application of portland cement plaster.

If plaster freezes, liquid water not bound up by hydration can turn to ice, potentially causing microcracking in the plaster coat. This issue may necessitate application of an additional base coat atop the compromised one.

Despite precautions, cold weather-applied portland cement plaster has a reputation for cracking more than plaster applied in moderate temperatures. Larger and more numerous cracks can show up months later, when the weather warms up.

The properties of rapid-setting cement address many of these cold weather issues. It achieves a high percentage of its ultimate strength within a few hours, reducing the time the material must be prevented from freezing. At 4 C – the lowest temperature recommended for application – initial set may take as long as three hours, which is twice as long as its 21-C (70-F) set time of 90 minutes. Nevertheless, the plaster’s matrix is well-formed and strong before nighttime temperature drops; a ‘four-hour’ job really does take four hours.5 Scratch and brown coats may often be performed in a single day under cold conditions. Moreover, the high water usage of CAS means barely any liquid water remains encapsulated within the plaster, leaving little to freeze.

Plastering schedules can be accelerated even further by using the material as a single-coat application.6 Two coats of portland cement plaster would each require an extended curing interval between coats because of the cold. In contrast, a contractor can apply the entire base coat of rapid-setting plaster in one fast pass and the finish coat the following day, which hastens enclosure of the building, removal of plasterer’s scaffolding, and jobsite cleanup.

When temperatures are constantly below 4 C day and night, tenting is required for any plastering operation. Under these conditions, a single-coat application saves two additional days of heating for each coat, and several weeks of waiting before applying the finish coat. It is also a ‘greener’ method as it reduces energy consumption and associated carbon dioxide emissions by minimizing the number of trips to the jobsite.

Contractors report little, if any, cracking of the rapid-setting plaster projects during the following months; cracks that do occur tend to be very fine.

Hot and dry

Just as the cold slows chemical processes down, heat speeds them up. In low-moisture environments, heat can hasten evaporation making it difficult to keep portland cement plaster sufficiently moist for long enough to cure properly.

Misting and covering the wall with plastic sheeting to retard drying is recommended, but has its limits. To avoid damaging new plaster’s texture, sheeting cannot be applied until set has been achieved, by which time much vital moisture can be lost. Wind can also get under the sheeting, spiriting moisture away. Keeping the plaster moist for several days under these conditions is problematic—actual work frequently falls short of best practice. The result is often severe drying shrinkage cracking.

Rapid-setting plaster also requires water curing, but for a much shorter period. It needs misting for at least 90 minutes after fi nal fi nishing, or until the surface cannot be easily scratched with a nail.7 It is then suffi ciently cured to apply the next coat, and drying is not a concern.

Wet, wet, wet

In regions prone to frequent and heavy rain, tenting is often required to protect both plaster and plasterers from rain. This necessity is true for both portland cement and rapid-setting plaster.

The typical cracking of exterior portland cement plaster has discouraged its use in heavy rain regions such as the Pacific Northwest. However, the crack resistance provided by rapid-setting plaster restores this option to the design professional. The material combines fast curing with a low pH, making it viable for next-day coating with acrylic finishes or other paints and coatings, if desired.

In a recent project in Bellevue, Washington, a 22,300-m2 (240,000-sf) eight-story hotel was plastered through the wet winter months using rapid-setting plaster. Although plastering began in October 2007, delays that were unrelated to the work postponed completion until the spring. Temperatures were often near the lower limit for plastering, and the constant threat of heavy rain necessitated tenting attached outside the plasterer’s scaffolding. A three-coat system was used, including an integral color finish. (No paint was applied.) The general contractor reported an excellent result with no visible cracking.

Other causes of cracking

Drying shrinkage cracking should not be confused with plastic shrinkage cracking, which occurs from premature moisture loss while the plaster is still in its workable (plastic) state.

All plaster is vulnerable to cracking from building movement. Although it is more flexible, EIFS can also crack due to structural shifts.

Movement-induced cracks frequently occur at the corners of doors and windows, over joints in sheer-wall panels, or at interfaces between two different structural materials or systems (e.g. wood-frame and masonry). Building and foundation settling, wind loads, thermal expansion and contraction, and structural loading can all cause building movement.

Inclusion of control joints as per ASTM C 1063, Standard Specification for Installation of Lathing and Furring to Receive Interior and Exterior Portland Cement-based Plaster, helps minimize cracking from building movement and limits the spread of cracks that do occur. The Stucco Manufacturers Association (SMA) recommends best practices to minimize building movement typically caused by construction activities, such as fully loading roofs before applying scratch and brown coats, and installing drywall before the finish coat.

Dollars and sense

The economics of rapid-setting plaster are slightly different than its traditional portland cement counterpart. In general, materials cost of rapid-setting plaster is higher, but mobilization costs are lower. The percentage of labor savings varies depending on regional rates and project size (i.e. economies of scale). Any project where other activity must wait for plastering to complete would obviously benefit from elimination of curing delays.

In rapid-setting plaster jobs performed under moderate temperature conditions, the net effect of savings versus increased expenses either balances out or results in cost reduction. In cold-weather applications, eliminating wait times and reducing or removing heating concerns heavily favor the economics of rapid-setting plaster.

EIFS and rapid-setting plaster are roughly comparable in materials cost and application time.

An additional benefit to architects, contractors, and owners is a more reliable result, which may lead to fewer repairs throughout the service life of the building envelope. Accelerated plastering schedules have helped general contractors avoid delay penalties, which can also benefit the owner – the contractor is less tempted to cut corners that gain time but lower the overall quality of work.

Applicators of rapid-setting plaster should be certified by the manufacturer to ensure best results.

This certification should include education in the workflow adjustments that must be made when switching to rapid-setting plaster. It also makes certain the applicator is fully conversant with the unique properties of the material and understands the best practices for obtaining optimal quality.

Conclusion

Although rapid-setting plaster is not based on portland cement, it is best specified under Section 09 24 00–Portland Cement Plastering. This incongruity is being reviewed by the Construction Specifications Institute’s (CSI’s) MasterFormat Maintenance Task Team. While proprietary guide specifications are available from CAS cement manufacturers, master specifications for portland cement plastering can be modified to include brand names, International Code Council (ICC)-approval numbers, or performance characteristics of rapid-setting plaster, such as high early compressive strength, quick set time, and maximum allowable drying shrinkage. Even when its extra durability is not a design requirement, rapid-setting plaster can be specified alongside portland cement plaster to allow contractors the option of using the material that best suits their jobsite schedules and conditions.

In extreme weather environments, rapid-setting plaster can be specified to access the beauty and durability of a traditional plaster finish while still minimizing the risks and costs associated with portland cement plastering. Applicators must be certified to use rapid-setting plaster, ensuring the material is handled properly. Combined with best practices, it helps minimize the risk of cracking.

Despite its numerous benefits, rapid-setting plaster is not yet ubiquitous as it is fairly new to the industry. Understanding its attributes can help design professionals select this innovative product for suitable projects.

REFERENCES

1 Typical set times based on 21 C (70 F) ambient and materials temperature.

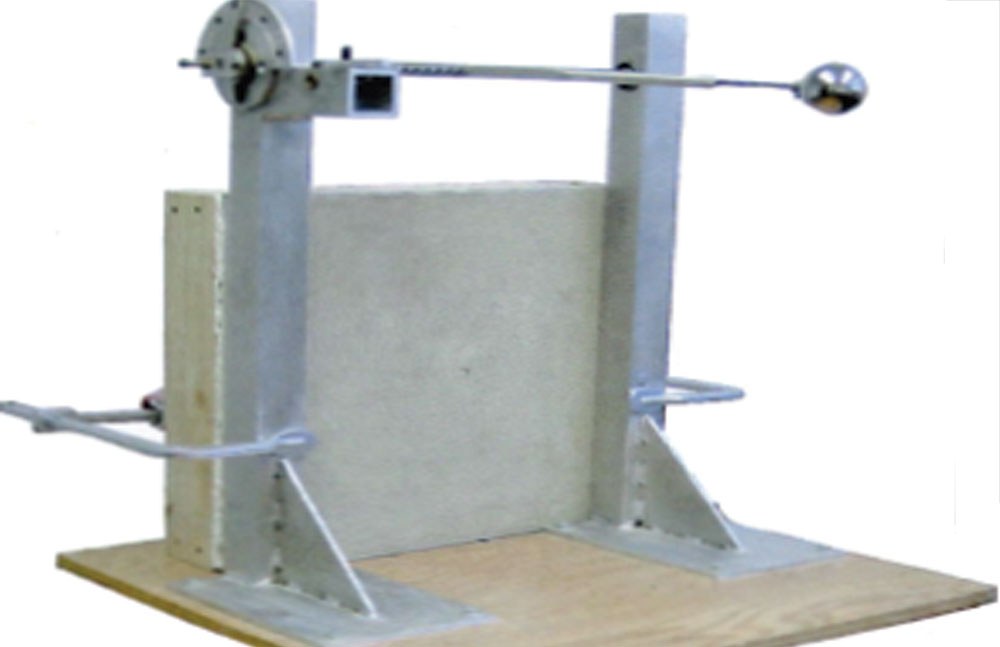

2 See Ken Vallens, Eric Bescher, J.D MacKenzie, et al.’s “A New Technique for the Measurement of Impact Resistance of Wall Coatings,” Cement and Concrete Research No. 31 (2001), based on a study performed at the Department of Materials Science and Engineering, UCLA, in 1998.

3 The 2003 International Building Code (IBC) Section 2512, “Exterior Plaster,” mandates a minimum 48 hours of moist curing for both scratch and brown coats, a 48-hour interval between scratch and brown coats, and a seven-day interval between brown and finish coats. To minimize cracking, some applicators extend these times to one week between scratch and brown coats, and two to three weeks between brown and finish coats.

4 In practice, many contractors find it prudent to extend this heating period up to three days, since all stages of curing are slowed by the cold.

5 Rapid-setting cement should not be confused with high-early-strength (Type III) portland cement. Type III portland cement, when used in concrete for instance, achieves compressive strength more quickly than Types I, II, or V. However, its ultimate (28-day) strength is sometimes lower for a comparable mix design. Rapid-setting cement is a chemically different material. It has higher ultimate strength and impact resistance than comparable mixes of portland cement plaster.

6 Approved under ICC ESR-2671, 19 to 25 mm (¾ to 1 in.) thick. In plastering terminology, ‘single-coat application’ refers to scratch and brown in a single coat; an additional 2-mm (¹⁄8-in.) finish coat would still be customary, so there are actually two coats in a single-coat application. The term ‘three-coat system’ refers to scratch, brown, and finish coats.

7 Although the ICC certification of the material as a single-coat application actually requires only one hour of misting, 90 minutes is recommended.

Written by: Conrad Bigelow, Creighton Maher, and Michael Chusid, RA, FCSI, Authors: Conrad Bigelow is a 32-year veteran of plastering. He has extensive experience as a plastering contractor and has owned a plastering company. Bigelow provides technical support for premium cement for exterior plaster at CTS Cement Manufacturing Corporation. He can be reached via e-mail at cbigelow@ctscement.com.Creighton Maher has 35 years of experience in residential and commercial construction. He also provides technical support for premium cement for exterior plaster at CTS Cement Manufacturing Corporation. Maher can be reached at (619) 992-9991. Michael Chusid, RA, FCSI, is president of Chusid Associates, a consulting fi rm specializing in technical and marketing services for advanced building products and materials. He can be contacted via www.chusid.com.

MasterFormat No.: 09 24 00–Portland Cement Plastering. UniFormat No.: B2010–Exterior Wall Exterior Skin.

CTS Cement Manufacturing Corp. is the leading manufacturer of advanced calcium sulfoaluminate (CSA) cement technology in the United States. Our Komponent® and Rapid Set® product lines are renowned for proven performance, high quality, and exceptional service life. Contact CTS Cement for support on your next project.

Call 1-800-929-3030

Original publication: Bigelow, C., Maher, C. and Chusid, M, RA, FCSI. (2007, December). Plastering for Extream Weather, 42-49.

THE IMPORTANCE

OF PLASTER AND SAND

Although the dominant ingredient of plaster by volume is sand, insufficient attention is paid to using the right type of sand in the correct quantity. Both aspects are vital for achieving optimal results.

Plaster sand is a specialized material. Size distribution of sand particles is defined in ASTM C 897, Standard Specification for Aggregate for Job-mixed Portland Cement-based Plasters. However, sand type is equally important—sharp-edged sand grains bond and interlock better, whereas river- or beach-sand grains are too smooth.

In some regions, plaster sand is a common commodity.

In other places, it is not available as a special product, making it likely that inappropriate material will be substituted.

Volume, rather than weight, is key to the ratio of sand to cementitious material. Cement paste tends to fill the spaces between sand grains; a proper mix is 75 to 85 percent sand by volume. If the sand is improperly graded—causing sand grains to have larger or smaller amounts of space between them—the mix will not have the proper performance properties. Standard proportioning (such as given in ASTM C 897) assumes sand that meets the grading standards.

Mixing instructions can also influence quality control. When printed on stucco materials, these directions are sometimes given in shovelfuls of sand versus bags of cement, which leaves much room for interpretation. Shovels can be heaped up to different degrees, depending on worker’s practice and sand flowability. In addition to affecting the amount of sand staying on a shovel, sand wetness may introduce excessive and unaccounted-for water into the mix. If dry sand from the edge of the pile gets used in a day’s first batch, and wet sand from the center goes into the second batch, the plaster will be inconsistent. In practice, this means the applicator proportions the sand to his or her convenience for workability, and not necessarily for the best ultimate result. A contractor may also be tempted to add too much sand, either for economic reasons or because he or she underestimated the quantity of cement needed.

In places where appropriate plaster sand is unavailable, the workforce’s experience in mixing plaster is questionable, or the result is critical, it may be advisable to specify premixed bagged plaster products to ensure the right quality and quantity of sand in the mix.