Project: US 53 Full-Depth Panel Replacement

Location: US 53, Eau Claire, Wisconsin

Dates: Memorial Day - Labor Day 2025

Team: Wisconsin DOT, Chippewa Concrete Services, and CPR Construction

Product: Rapid Set® Cement

Project Overview

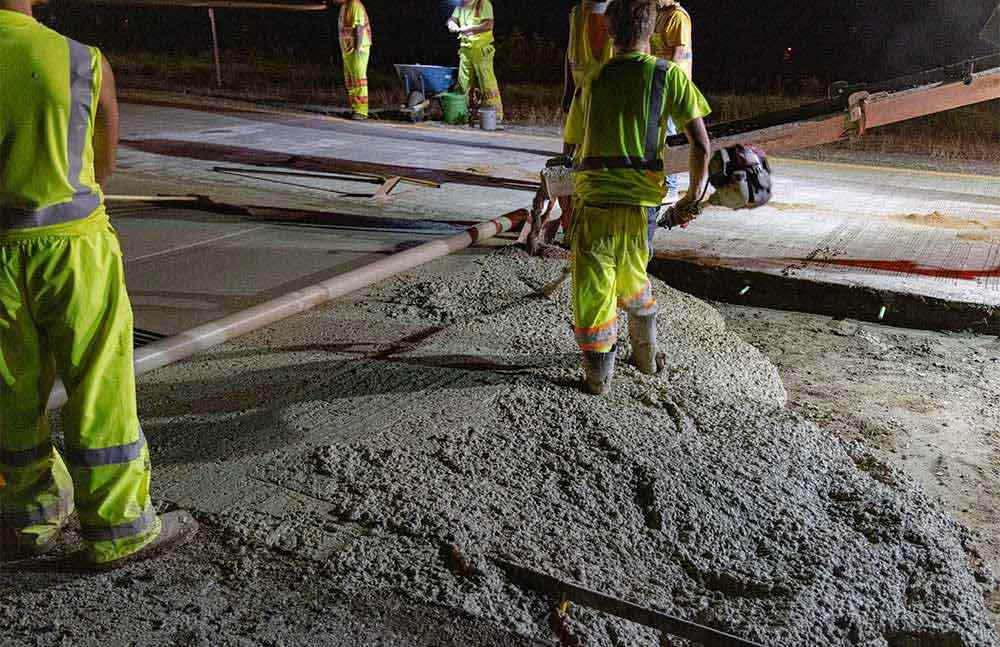

The US 53 Full-Depth Concrete Panel Replacement project is a showcase of large-scale, rapid-setting concrete restoration within a highly trafficked state corridor. Located in Eau Claire, Wisconsin, one of the Midwest’s key summer tourism and freight corridors, this project addressed critical infrastructure needs on a compressed Memorial Day to Labor Day timeline. Partnering with the Wisconsin DOT, prime contractor Chippewa Concrete Services, and volumetric producer CPR Construction, the CTS team supplied over 2,200 tons of Rapid Set® Cement used to produce 7,400 cubic yards of full-depth concrete pavement replacement—all poured overnight to avoid daytime disruption. The project not only met strict 6:00 a.m. reopening deadlines with $600-per-minute penalties for delays, but also helped influence statewide specification changes toward CSA cement.

Project Size

The project involved 22,000 square yards of full-depth panel replacements along US 53. CPR Construction, using volumetric trucks, placed approximately 7,400 CY of Rapid Set-based concrete. The scope required nightly placements, traffic control coordination, and real-time site adjustments based on field conditions.

Project Difficulty

The project presented multiple technical and logistical challenges:

Uniqueness

This was the largest CSA-based rapid-setting project ever completed in Wisconsin and the first high-production DOT job to use Rapid Set Cement exclusively. The project leveraged deep collaboration with the Wisconsin Concrete Paving Association (WCPA), which advocated for the approach alongside CTS. Their involvement gave third-party validation to the process, which proved critical in updating the state’s approach to patching specifications.

Innovative Construction Methods

The team employed several innovations to meet project needs:

This job was also used to demonstrate how volumetric batching can be scaled up to support DOT-level production targets.

Use of Materials

2,200 tons of Rapid Set Cement were used to produce 7,400 CY of high-performance concrete. Key mix attributes included rapid strength gain, low shrinkage, and consistent flow. The concrete achieved opening strength (>2400 PSI) in under 2.5 hours in all placements. Notably, no test cylinders failed, and the materials were delivered through a just-in-time logistics model built around railcar delivery and field storage management.

How Rapid Set Helped Overcome Challenges

Rapid Set Cement was fundamental to overcoming several obstacles:

Additionally, Rapid Set’s reliability gave the DOT confidence to explore CSA specification adoption statewide.

Project Results

The project was completed on schedule with zero failed strengths, no missed morning openings, and no penalties incurred. It demonstrated the viability of volumetric batching at scale for DOT use, influenced Wisconsin DOT to rewrite its patching specifications to include CSA cements, and proved to nearby states (e.g., Indiana, Ohio) that Rapid Set offers a real-world, scalable alternative to traditional mixes.

The collaborative approach by linking CTS technical staff, contractors, WCPA representatives, and state engineers created a repeatable model for future DOT projects across the Midwest.

Think Your Project Has What It Takes?

Want to learn more about our Projects of the Year Awards or have a project to enter? Explore the awards program and submit your project. Submissions are open through October 31, 2026, across four categories celebrating excellence in concrete construction and design.